1006 Morton Street

Baltimore, MD 21201

410.576.9131 | RW1haWw=

September 15 2010

What is a Ground-Air Heat Exchanger?

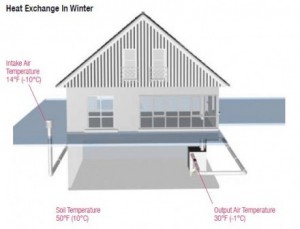

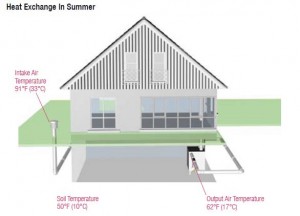

So what do sustainable designers know when they advocate installing a Ground-Air Heat Exchanger? Well it turns out that the soil around your building is a tremendous resource that can significantly improve the overall energy efficiency of a mechanical system. Whether a building needs cooling in the summer or heating in the winter, the relatively stable temperature of soils between 5 to 7 feet below the surface, provide an ideal means of bringing incoming ventilation air closer to the desired indoor air temperature without expending significant energy. The system doesn't generate energy per se, nor is it entirely passive, but it can be a potent component used to optimize the efficiency of a mechanical system, especially when strict ventilation requirements need to be met. Sustainable designers understand that 'free' energy shouldn't be passed up and that Ground-Air Heat Exchangers (GAHE)are a very robust, reliable and effective way of harvesting that potential energy.

GAHE is not a geothermal system. It does not use heat from deep within the earth to actively power a building. Instead GAHE exchanges energy between a fluid medium (air in this case) and the earth in a system which is high volume with low energy intensity. Note that Ground-Air Heat Exchangers do however go by many other names including: Earth tubes, air-to-soil HX, earth channels, earth canals, earth-air tunnel systems, ground tube HX, hypocausts, subsoil HX, underground air pipes, and more (see wiki).

GAHE systems are nothing new. In fact the Romans first used a type of GAHE in what would become their great hypocausts heating the caldariums and tepidariums of their great bathhouses. These underground chambers, constructed as they were into the foundations of buildings, where essentially passages where heat or coolth was exchanged between hot furnaces or the cool ground as a way of conditioning rooms above to the desired temperature. While the hypocaust system is rarely built today, the GAHE concept is still common in Europe where a tradition of low energy buildings, lengthy perceived life-cycles for structures, and a broader interpretation of the human comfort range, make the systems very attractive.

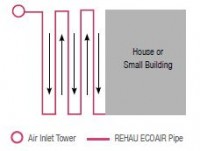

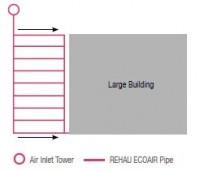

There is no standardized equipment or configuration for a GAHE but the systems generally include similar components starting with an air intake tower which is located at a distance from any pollutant sources such as driveways, exhaust ducts, or trash cans. This prevents contamination of the ventilation air. A rain hood incorporating filter media is often used to prevent animals, insects and other smaller contaminants from being introduced to the system. Subsoil piping, the heart of the Ground-Air Heat Exchange process, can be made from a number of different materials including concrete, PVC, and steel (among others) but it is important to note that the diameter, layout and cleanliness of the piping is critical to the overall performance of the system. For instance right now there is an open debate about the best piping material to use. At the Aldo Leopold Center concrete culverts were chosen because of cost and availability where-as an anti-microbial PVC was selected for the Waldsee Biohaus. One might consider one solution versus another out of concern for price, ease of installation, availability, and air quality.

The diameter, length and layout of the piping are also essential to the performance of the system. High CFM might prevent the correct transference of energy between the ground and the air while low CFM might allow moisture to build up causing air quality problems. The system can be too short to fully capture energy from within the soil, but it can also be too long thereby increasing unnecessarily pressure drop within the piping. A good sign that the piping is designed correctly is that the system is balanced - meaning that the pressure is equal thoughout the pipes. Finally GAHEs most likely cause the outside air to reach dew point and therefore need to have a way of managing condensation through condensate drains, direct seepage or sump pumps.

Remember that the GAHE is only a part of the mechanical system and simply supplies the ERV/Ventilation system with preconditioned air. Using a GAHE does not preclude one from having a mechanical system (unless you are designing for northern California) whose design must be handled by a professional.

Ecoair by Rehau

One of the best engineered of the GAHE systems is called Ecoair by Rehau. What makes the system unique is that it comes with a pre-engineered set of parts which include a rather sexy looking 6ft tall stainless steel inlet tower with a replaceable air filter, correctly sized PVC piping with an innovative silver antimicrobial inner layer called Agion, a robust pipe gasketing system to prevent groundwater infiltation, and two specially designed condensation management systems. According to the product page:

The Rehau Ecoair ground-air heat exchange system capitalizes on the relatively constant ground temperatures found 5 to 7 feet (1.5 to 2 meters) below the earth's surface. Before entering a building's indoor ventilation system, fresh air is pre-warmed with ground heat in winter, and pre-cooled with cooler ground temperatures in summer. For example, in mid-latitude North America, where ground temperatures are 45°F to 54°F (7°C to 12°C), REHAU ECOAIR can assist in raising the intake air temperature by up to 16°F (9°C) during colder months, and reducing it by up to 29°F (16°C) in the summer.

The touted benefits include:

- Provides controlled fresh air ventilation that is filtered for dust and allergens

- Significantly reduces the amount of additional energy required to heat and cool a building, especially when combined with a heat or energy recovery ventilator (HRV or ERV)

- Lowers the relative humidity

- May eliminate the need for several air conditioner units in temperate climates (learn here about the details)

- Requires only a small amount of electrical power to operate an air intake fan

- May eliminate the need for defrost cycle in an HRV

This system has been deployed extensively and with great success in Europe but has only a limited number of installations here in the US. The main obstacles to adoption here in the States appear to be lingering questions about the air quality (aka mold), cost, and the general awareness of the benefits of using the system. It is one thing to argue for the use of an earth tube when the building is already sustainable to some degree, it is another discussion altogether to introduce the concept of earth tube when sustainability is a distant target. To date, the two best case studies for the Ecoair system are the Waldsee Biohaus (the first US Passive House) and the Polk School (see the videos below.

For more information on GAHE please see Earth Tubes Cooling by the Department of Energy, the Ecoair System by Rehau, or the Earth Tubes Green Feature at the Aldo Leopold Foundation Building.

Recent Posts

Reimagining Harborplace to Create Space for Both Private Development and Expanded Public Space » Lawyer's Mall Reconstruction Progress » Confronting the Conventions of Customary Practice » Reconceived Facades: New Roles for Old Buildings » Ivy Bookshop Opens for Business! »

Categories

Yellow Balloon Baltimore » Products + Technology » Industry + Practice » Other » Architecture »

Links

Organizations

- USGBC Baltimore Regional Chapter »

- AIA - American Institute of Architects »

- USGBC »

- The Walters Art Museum »

- Green-e »

- Center for Building Performance and Diagnostics (CMU) »

- Green Globes »

- Prefab Lab (UT) »

- Center for Sustainable Development (UT) »

- Architecture 2030 »

- Bioneers »

- Street Films »

- FreeCycle »

- Chesapeake Bay Foundation »

- Archinect »

- BD Online - The Architects Website »

- National Wildlife Foundation »

- Natural Resources Defense Council »

- Overbrook Foundation »

- Merck Family Foundation »

- Ecology Center »

- New Building Institute »

- Neighborhood Design Center »

- The Leonardo Academy »

- ZigerSnead Architects LLP »

- The Rocky Mountain Institute »

- Urban Habitats »

- ACORE - American Council on Renewable Energy »

- Parks and People Foundation of Baltimore »

- Open Society Institute of Baltimore »

- Natural Capital Institute »

- Passive House US »

- Svanen Miljomark »

- Green Restaurant Association »

- Rocky Mountain Institute »

- Green Exhibits »

- Green Roundtable »

- John Elkington - SustainAbility »

- SustainAbility »

- Building America »

- Endangered Species Program - Fish and Wildlife Service »

- Congress for the New Urbanism »

- Urban Land Institute »

- Cool Roof Rating Council »

- Montgomery County (MD) Public Schools Green Building Program »

- National Institute of Standards and Technology Software »

- Scientific Certification Systems »

- Community Greens »

- CBECS »

- CASE - Center for Architecture Science and Ecology »

Interesting Sites

- The Ecologist »

- Treehugger »

- Grist »

- WIRED »

- Planet Architecture »

- MiljoBloggAktuellt - Environmental News Blog (Swedish »

- Sustainable Design Update »

- Eikongraphia »

- World Architecture News »

- The Cool Hunter »

- Design Center »

- ZEDfactory »

- Architen Landrell Associates Ltd. »

- Environmental Graffiti »

- businessGreen »

- Best Green Blogs Directory »

- Groovy Green »

- EcoGeek »

- Urban Ecology »

- Locus Architecture »

- Urbanite »

- A Daily Dose of Architecture »

- Adaptive Reuse »

- Audacious Ideas »

- Big Green Me »

- NOTCOT »

- Sustainable Baltimore »

- Thoughts on Global Warming »

- Green Maven »

- WorldChanging »

- Go For Change »

- Building Green »

- Home Energy Magazine »

- Home Energy Blog »

- FEMA Map Service- Federal Emergency Management Association »

- Architectural Graphic Standards »

- E-Wire »

- Post Carbon Cities »

- Alt Dot Energy »

- Whole Building Design Guide »

- B'more Green »

- EJP: Environmental Justice Partnership »

- Baltidome »

- OneOffMag »