1006 Morton Street

Baltimore, MD 21201

410.576.9131 | RW1haWw=

June 23 2008

Kelvin’s Conjecture: The Sustainability of Optimization and Integration

?to make as effective, perfect, or useful as possible? -Definition 'Optimize'

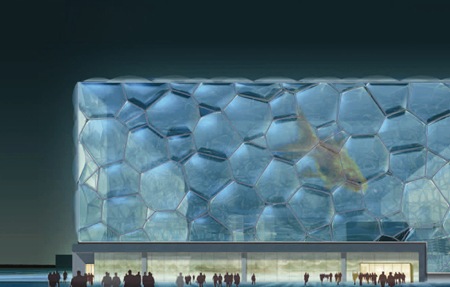

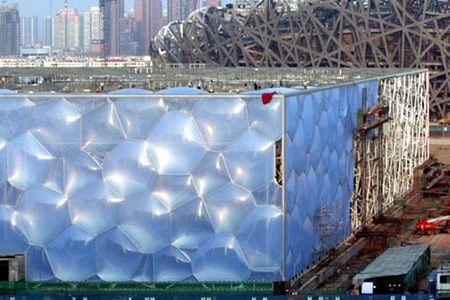

The National Aquatic Center in Beijing achieves sustainability through the optimization and integration of its structure, envelope, and building systems. In doing so it tells the story of how a little known problem of theoretical physics, Kelvin?s Conjecture, influenced the design of a prominent international building by leveraging advances in information sharing, computational modeling and materials science. Combination of these world ?flattening? innovations with architectural vision and pure science delivered a stunning and sustainable building. Furthermore, their integration describes a new paradigm in the building design process which is poised to revolutionize the practice of architecture. And sustainability, not obvious at first glance, permeates the design, materiality and final form of the Water Cube.

Interestingly, the project forced a blending of the disciplines and responsibilities of architects, engineers, contractors, materials developers and scientists. Each segmented discipline was asked to help solve issues related tangentially to their own domain. Integration was so rigorous in fact, that the building design necessitated the development of new advanced software for analyzing building behavior. The overall outcome was a integration of disciplines and mastery of technologies which is not always required on more traditional building projects.

Description

The 70,000 sq. meter National Aquatics Center, also known as the Water Cube, is being built for the 2008 Summer Olympics in Beijing, China at a cost of roughly $140 million dollars. Construction began in December of 2003 and was delayed past its 2006 deadline until January of 2008. It is located in the Olympic Green Precinct adjacent to Herzog and de Meuron?s Olympic Stadium. The center measures 170 meters long by 170 meters wide and is 31 meters tall. During the games it will hold over 17,000 spectators for the aquatics events.

Design Process

The project was conceived as part of a design competition won by the team of PTW Architects, Ove Arup Australasia, the China State Construction Engineering Corporation (CSCEC) and the Shenzhen Design Institute (CSCEC+Design). Interestingly, the brief, beyond just the programmatic requirements, included requirements for ?extensive use of digital technology, energy-reduction, water savings, and use of new construction materials?. From the start, these few simple inclusions in the design brief insured that the winning ?water cube? would exceed expectations in terms of design and delivery. Tristram Carfrae, of ARUP engineering notes:

?Unusually, we at Arup began the competition process by outlining to the architects what we wanted to achieve technically, based on our previous experience with aquatic centres; bringing into play a whole gamut of engineering disciplines.

As swimming pools need to be heated for most of the year, we decided that the solution that solved most of the technical problems was an insulated greenhouse. Diffused natural light would enter through a main steel structure built within a cavity, to isolate it from both the corrosive pool-hall atmosphere and from the outside. Arup also reasoned that ETFE, a transparent form of Teflon, would be most efficient for such a greenhouse, removing the need for a secondary structure and providing better insulation than single glazing. The architectural planning team concurrently calculated that the entire square site would be needed to fit all the required facilities into the centre.?

The ARUP engineer adds that the design for the ?water cube? was, in part, a reaction to the unveiling of the adjacent ?red birds? nest.? As a result, the submission, the ?water cube?, was conceived as blue box of bubbles. What the design team did not know was that the concept of a box of bubbles would lead them on a journey through obscure scientific research; that a beautifully simple concept might not point to a straightforward technical solution.

How then should the team technically achieve their vision?

The team first set about rationalizing the design concept as a series of vertical cylinders. The cylinders would have circular ETFE panels at the top and bottom. The problems with this solution are easily apparent however. Cylinders do not fit well together and what should happen at the intersection of vertical and horizontal surfaces? How are these areas rationalized and does that rationalization lead to a feeling of random bubbles?

At this point the team had to ask ?what sorts of shapes fill three dimensional space uniformly?? And what shape would give the impression of random bubbles?

In a precursor to the methodology used throughout the project, Tristram Carfrae notes that ?(He) suspected nature would provide the answer, from living cells to mineral crystals.?

Kelvin?s Conjecture

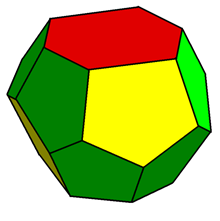

?How can space be partitioned into cells of equal volume with the least area of surface between them.? ? Lord Kelvin, Kelvin?s Conjecture, 1887

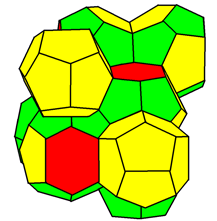

The design team found that they were not alone in asking this question. Theoretical physicists had been trying to solve Kelvin?s Conjecture for over one hundred years. Kelvin himself proposed that the solution was a 14-sided polyhedron with six square sides and eight hexagonal sides. Kelvin?s solution was considered most efficient for over a hundred years. That was until in 1998 when two physicists, Denis Weaire and Robert Phelan, using computer generated simulations of foam, found a more efficient solution. Their solution was in fact 0.3% more optimized. It is composed of two types of cell: an irregular pentagonal dodecahedron and a tetrakaidecahedron with 2 hexagons and 12 pentagons. Some with slightly curved surfaces. This solution is known as the Weaire-Phelan Structure. It was perfect.

The only remaining problem was that the solution when modeled appeared to orderly. The size and shape of the ?bubbles? was too regularized to be plausible as the solution to a ?box of bubbles.? The Weaire-Phelan structure delivered again because it was soon discovered that the structure, when sliced at arbitrary angles, appears ?totally random and organic.? The solution was therefore to conceive of a larger block of ?bubbles? rotate it and slice the ?water cube? geometry out.

It is important to note however that the façade is not entirely random. Out of a total of 4,000 bubbles there are only 22 variations of ETFE panel in the entire project (15 at vertical surfaces and 7 at horizontal).

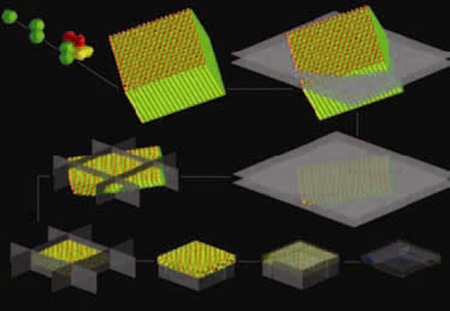

New Software / BIM

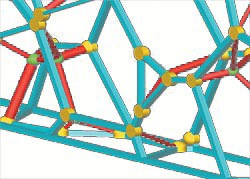

Once the competition was won the team then had to set about actually engineering the structure. The Weaire-Phelan structure was optimized to use the minimal amount of surface area between elements. But that does not translate directly into an efficient structural system for a building. Somehow designers needed to figure out a way to test the structure and size the 22,000 steel tubes, 12,000 steel nodes, and 4,000 bubble panels that form the exterior cladding. The response by the ARUP team is astounding. They designed a new software package to optimize the structural system of the façade.

?[?]the structural optimization process sized all the steelwork members and their connections.?

The software then ported all this data into an accurate 3D CAD model that could be used to create construction drawings. The software package was developed enough so that in event of a major change in scope or design, it could re-engineer the entire structural system automatically in about a week. Instant building plans!

Fire, smoke and egress requirements were a second area where performance based simulation was extensively used. It was very important for the viability of the structure to prove that the individual steel members did not need to be covered in fire spray or fire resistant intumescent paint. In this case a modeling package called Fire Dynamic Simulation was used to provide data to Chinese authorities. Using the data engineers proved that the structure would resist fire for long enough to be safe as long as added measures such as sprinklers were used.

Critical too was the use of ETFE as the interior and exterior cladding. The design team had to prove that it would not be dangerous to clad the building in a plastic material. ETFE is, after all, a combustible material. The saving grace of ETFE is that it shrinks away from heat. This means that the building envelope is essentially self ventilating. It allows smoke to escape right through the building membrane giving occupants critical extra time to exit the building.

Building Performance

The ?water cube? is designed to be a greenhouse. Two layers, an exterior and interior, of ETFE create a double membrane barrier mediating the exterior and interior conditions. This arrangement has an effective ?negative U-value? because the building envelope is able to capture more heat energy in the form of solar radiation, than it looses through convection, conduction or radiation back out through the facade. Furthermore, the high thermal mass of both the pool water and the concrete structure around the pool ensure that heat remains in the building during the nightly cooling period. Designers predict that this strategy will help cut pool hall energy consumption by over 30%!

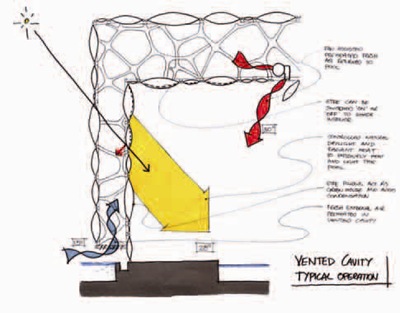

Overheating could be a problem however. The designers therefore selected a ?frit? patterning on various layers of the ETFE in order to reduce heat gain in the summer and maximize heat gain in the winter. A second strategy of ventilation within the exterior envelope, between exterior and interior layers of ETFE, keeps the envelope tempered year round.

Stratification and displacement are important concepts to the energy efficiency of the building. Engineers allow the air within the pool hall to stratify so that the entire volume does not have to be brought into comfort ranges. This in combination with a displacement conditioning system that brings tempered air directly to the user at the bottom of the volume reduces energy consumption by a factor of ten. Excess heat from the condenser units is also used to heat the pool water. In combination, these strategies significantly lowered the energy footprint of the building beyond what a typical aquatic center would require.

Conclusion

The ?water cube? is sustainable because of it?s optimization. Optimization of concept. Optimization of skin. Optimization of structure. Optimization of energy use. Optimization of fire control. Optimization in the water cube occurred at many scales and across many strategies, and they all worked in concert to deliver a building design that was more sustainable than any one part taken independently. We have seen how this optimization occurred.

The competition brief catalyzed an integration of ideas at the inception of the design process. The involvement of ARUP, and specifically their statement of the critical performance criteria for an aquatics center early on in the design process drove the direction of the project. In fact that early injection of a scientific method into the process allowed architects and engineers to benefit from one another?s experience and knowledge and left the door open to investigations outside the realm of pure ?building? sciences.

Asking the right fundamental questions, on the part of ARUP engineer Tristram Carfrae, made possible the uncovering of Kelvin?s Conjecture and the eventual optimization of the entire building structure. Advances in material science allowed the design team to select materials with appropriate properties for the project. With regard to smoke evacuation and heat gain, designers were able to customize ETFE to suit their exact specifications. In addition, simulation software helped optimize the structure, systems and operation of the building before any construction began. This gave the client the confidence to sign off on the design even with a very ambitious proposal.

The process was made possible by advances in simulation technology, material science, and information sharing that are just starting to affect the way our built environment is created.

The results are breathtaking.

For more information please review the following reference articles:

Ingenia Online - Box of Bubbles

Guardian Newspaper - Welcome to the WaterCube

Design Build Network - Water Cube

Recent Posts

Reimagining Harborplace to Create Space for Both Private Development and Expanded Public Space » Lawyer's Mall Reconstruction Progress » Confronting the Conventions of Customary Practice » Reconceived Facades: New Roles for Old Buildings » Ivy Bookshop Opens for Business! »

Categories

Yellow Balloon Baltimore » Products + Technology » Industry + Practice » Other » Architecture »

Links

Organizations

- USGBC Baltimore Regional Chapter »

- AIA - American Institute of Architects »

- USGBC »

- The Walters Art Museum »

- Green-e »

- Center for Building Performance and Diagnostics (CMU) »

- Green Globes »

- Prefab Lab (UT) »

- Center for Sustainable Development (UT) »

- Architecture 2030 »

- Bioneers »

- Street Films »

- FreeCycle »

- Chesapeake Bay Foundation »

- Archinect »

- BD Online - The Architects Website »

- National Wildlife Foundation »

- Natural Resources Defense Council »

- Overbrook Foundation »

- Merck Family Foundation »

- Ecology Center »

- New Building Institute »

- Neighborhood Design Center »

- The Leonardo Academy »

- ZigerSnead Architects LLP »

- The Rocky Mountain Institute »

- Urban Habitats »

- ACORE - American Council on Renewable Energy »

- Parks and People Foundation of Baltimore »

- Open Society Institute of Baltimore »

- Natural Capital Institute »

- Passive House US »

- Svanen Miljomark »

- Green Restaurant Association »

- Rocky Mountain Institute »

- Green Exhibits »

- Green Roundtable »

- John Elkington - SustainAbility »

- SustainAbility »

- Building America »

- Endangered Species Program - Fish and Wildlife Service »

- Congress for the New Urbanism »

- Urban Land Institute »

- Cool Roof Rating Council »

- Montgomery County (MD) Public Schools Green Building Program »

- National Institute of Standards and Technology Software »

- Scientific Certification Systems »

- Community Greens »

- CBECS »

- CASE - Center for Architecture Science and Ecology »

Interesting Sites

- The Ecologist »

- Treehugger »

- Grist »

- WIRED »

- Planet Architecture »

- MiljoBloggAktuellt - Environmental News Blog (Swedish »

- Sustainable Design Update »

- Eikongraphia »

- World Architecture News »

- The Cool Hunter »

- Design Center »

- ZEDfactory »

- Architen Landrell Associates Ltd. »

- Environmental Graffiti »

- businessGreen »

- Best Green Blogs Directory »

- Groovy Green »

- EcoGeek »

- Urban Ecology »

- Locus Architecture »

- Urbanite »

- A Daily Dose of Architecture »

- Adaptive Reuse »

- Audacious Ideas »

- Big Green Me »

- NOTCOT »

- Sustainable Baltimore »

- Thoughts on Global Warming »

- Green Maven »

- WorldChanging »

- Go For Change »

- Building Green »

- Home Energy Magazine »

- Home Energy Blog »

- FEMA Map Service- Federal Emergency Management Association »

- Architectural Graphic Standards »

- E-Wire »

- Post Carbon Cities »

- Alt Dot Energy »

- Whole Building Design Guide »

- B'more Green »

- EJP: Environmental Justice Partnership »

- Baltidome »

- OneOffMag »

June 24th, 2008 at 2:22 AM

Greenline » What is Ethylene Tetraflouroethylene (ETFE)?

[...] Such strategies can help buildings appear very dynamic as spatial elements. In the case of the National Aquatics Center in Beijing the ETFE pillows are fritted according to a solar / programmatic study to make best use of solar [...]