1006 Morton Street

Baltimore, MD 21201

410.576.9131 | RW1haWw=

February 27 2011

9/11 Memorial of Maryland: 3D Scanning an Artifact from the Twin Towers

(This post is part of a series on the 9/11 Memorial of Maryland which is being designed by Ziger/Snead - for images of the artifact visit the project page)

How does one measure, or model, an artifact that is large yet detailed, twisted yet graceful, heavy yet delicate, hulking yet revered? The 9/11 Memorial of Maryland has, at its center, a twisted mass of three amalgamated steel beams over 20' long (with an associated smaller steel shard) taken directly from the structure of the Twin Towers. This is not an easy object to put a tape measure on. Can a straight edge define this surface? Can a pencil sketch document this texture? Certainly not with any accuracy.

Documentation of existing conditions is the starting point for almost every design project and while in buildings this can be challenging but manageable, the complexity of the 9/11 Artifact meant that Ziger/Snead had to look beyond our traditional tools for a solution.

It is worth noting that Ziger/Snead believes the design and construction process should have almost no impact on the 9/11 Artifact itself as an expression of reverence. Stabilization. Preservation. Mounting. Labeling. None of these actions should alter the Artifact more than absolutely necessary and this attitude precludes the use of many traditional measuring techniques used in architecture, sculpture, and design where the subject might become damaged. There is however, a sophisticated set of digital tools designed specifically to capture and model complex three dimensional geometric objects for the aviation, automotive, military and product design industries, namely 3D scanning. We always seek out the best consultants, and in this case the world's best happen to be right here in Maryland!

DirectDimensions of Owings Mills MD is "the world's leading authority on the application of geometric measurement technology" and were brought on the 9/11 Memorial of Maryland design team to help us document the Artifact. The technology is fascinating and is succinctly described by DirectDimensions as:

"measure[ing] in three-dimensional space - x, y, and z - using advanced 3D scanning systems. [Then] putting data together like a virtual puzzle [to] create an exact 3D digital model. What makes this technology so remarkable is its ability to pick up fine details, such as sculpted lines, engraved names, even barely visible marks so that the "copy" is an exact replica - something that could never be accomplished with conventional measurement methods. As data is collected, the object becomes visible on the computer screen as a point cloud and can be studied and manipulated in remarkable detail.

The point clouds are then processed into digital models by our engineers using a series of software. Depending on the final goal, the digital models can be used as visual animations, design intent CAD models, or even models for physical replication at any scale."

Below are images (taken by photographer Bill McAllen) showing the scanning taking place at the Artifact storage location. You can see that two different types of scanning were done. The first a pole mounted scanner and the second a hand held unit to get more detail about the Artifact. The output is shown further down.

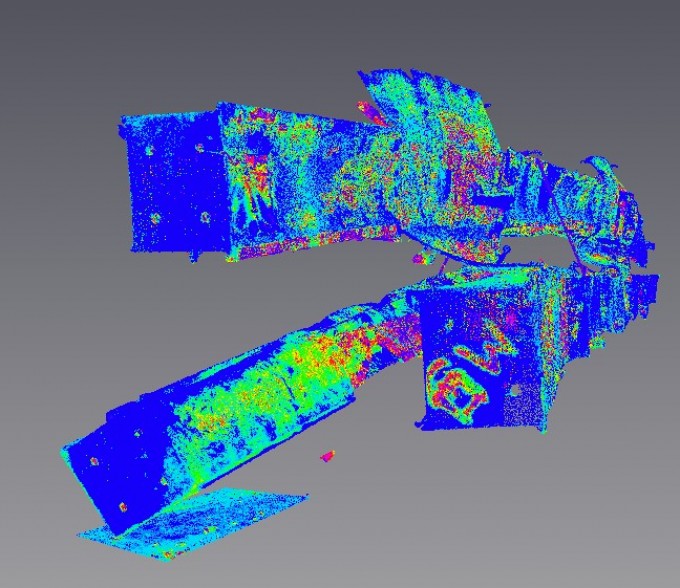

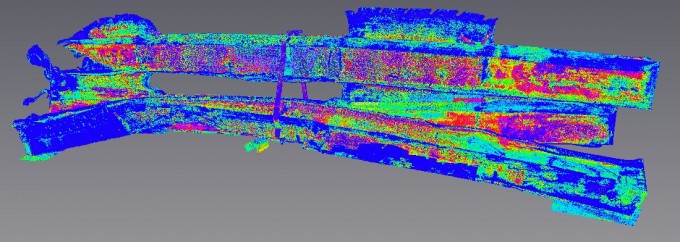

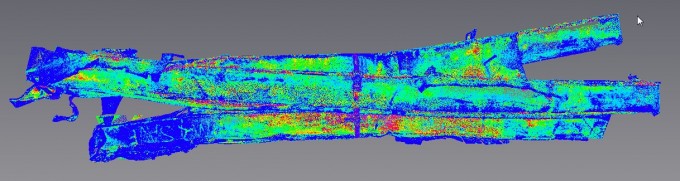

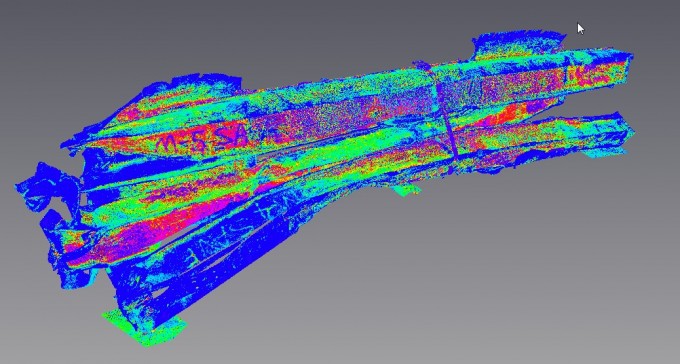

Below are point cloud views of the Artifact...

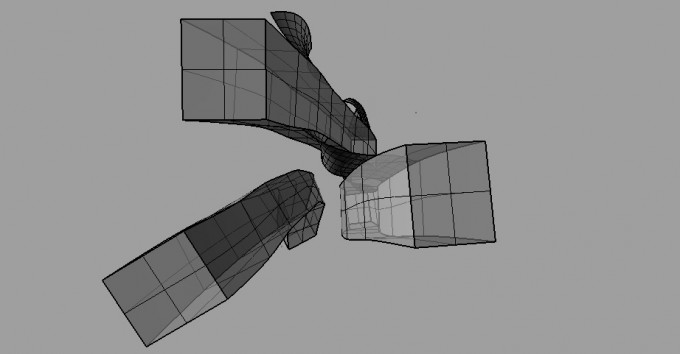

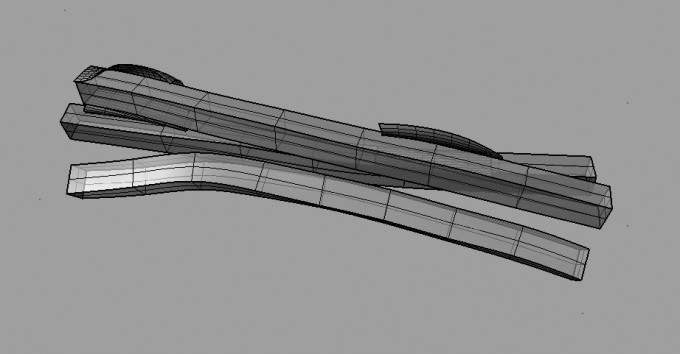

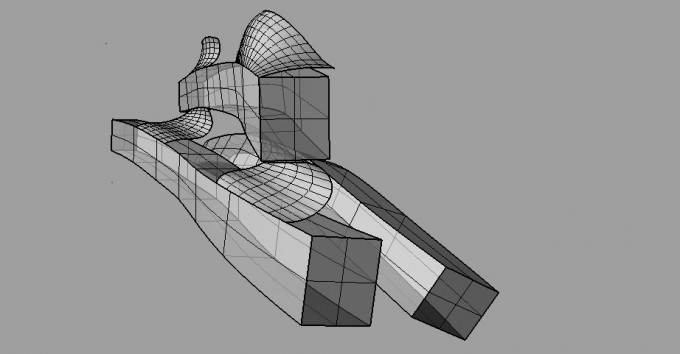

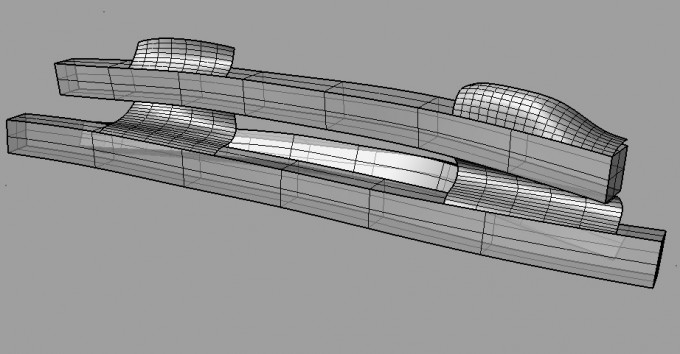

Below are simplified 3D geometric views of the Artifact...

Amazing isn't it?! As the images above show, the technology does a splendid job of converting complex physical data into digitized computer files that can then be translated in 3D models of varying complexity to suit the needs of the design. There are a number of opportunities available to the design team now given the sophistication of the data we now have to use. Examples include 3D printing of scale models of the Artifact, using rough 3D models for placement on the project site and construction questions, and employing detailed 3D models for design of structural supports and fasteners. None of these would be possible if we didn't have this technology available.

Ziger/Snead always uses the latest tools and strategies to make better architecture and this is a perfect example of a transformative technology. Call it sustainability through optimization. 3D scanning of construction sites, existing buildings, and design models is already taking place and will allow smarter, more efficient design to be carried out in future projects. We look forward to incorporating this technology into our projects.

For more information including photos of the Artifact please visit the 9/11 Memorial of Maryland project page or visit the DirectDimensions company website for more info on 3D scanning. Also visit the Maryland State Arts Council for more information on the project as a whole.

posted by Jonas Risen

Recent Posts

Reimagining Harborplace to Create Space for Both Private Development and Expanded Public Space » Lawyer's Mall Reconstruction Progress » Confronting the Conventions of Customary Practice » Reconceived Facades: New Roles for Old Buildings » Ivy Bookshop Opens for Business! »

Categories

Yellow Balloon Baltimore » Products + Technology » Industry + Practice » Other » Architecture »

Links

Organizations

- USGBC Baltimore Regional Chapter »

- AIA - American Institute of Architects »

- USGBC »

- The Walters Art Museum »

- Green-e »

- Center for Building Performance and Diagnostics (CMU) »

- Green Globes »

- Prefab Lab (UT) »

- Center for Sustainable Development (UT) »

- Architecture 2030 »

- Bioneers »

- Street Films »

- FreeCycle »

- Chesapeake Bay Foundation »

- Archinect »

- BD Online - The Architects Website »

- National Wildlife Foundation »

- Natural Resources Defense Council »

- Overbrook Foundation »

- Merck Family Foundation »

- Ecology Center »

- New Building Institute »

- Neighborhood Design Center »

- The Leonardo Academy »

- ZigerSnead Architects LLP »

- The Rocky Mountain Institute »

- Urban Habitats »

- ACORE - American Council on Renewable Energy »

- Parks and People Foundation of Baltimore »

- Open Society Institute of Baltimore »

- Natural Capital Institute »

- Passive House US »

- Svanen Miljomark »

- Green Restaurant Association »

- Rocky Mountain Institute »

- Green Exhibits »

- Green Roundtable »

- John Elkington - SustainAbility »

- SustainAbility »

- Building America »

- Endangered Species Program - Fish and Wildlife Service »

- Congress for the New Urbanism »

- Urban Land Institute »

- Cool Roof Rating Council »

- Montgomery County (MD) Public Schools Green Building Program »

- National Institute of Standards and Technology Software »

- Scientific Certification Systems »

- Community Greens »

- CBECS »

- CASE - Center for Architecture Science and Ecology »

Interesting Sites

- The Ecologist »

- Treehugger »

- Grist »

- WIRED »

- Planet Architecture »

- MiljoBloggAktuellt - Environmental News Blog (Swedish »

- Sustainable Design Update »

- Eikongraphia »

- World Architecture News »

- The Cool Hunter »

- Design Center »

- ZEDfactory »

- Architen Landrell Associates Ltd. »

- Environmental Graffiti »

- businessGreen »

- Best Green Blogs Directory »

- Groovy Green »

- EcoGeek »

- Urban Ecology »

- Locus Architecture »

- Urbanite »

- A Daily Dose of Architecture »

- Adaptive Reuse »

- Audacious Ideas »

- Big Green Me »

- NOTCOT »

- Sustainable Baltimore »

- Thoughts on Global Warming »

- Green Maven »

- WorldChanging »

- Go For Change »

- Building Green »

- Home Energy Magazine »

- Home Energy Blog »

- FEMA Map Service- Federal Emergency Management Association »

- Architectural Graphic Standards »

- E-Wire »

- Post Carbon Cities »

- Alt Dot Energy »

- Whole Building Design Guide »

- B'more Green »

- EJP: Environmental Justice Partnership »

- Baltidome »

- OneOffMag »