1006 Morton Street

Baltimore, MD 21201

410.576.9131 | RW1haWw=

November 17 2009

The Reinvention of Wood through Sustainable Tech

Wood, arguably the most timeless of materials, is being reinvented (re-engineered) by sustainable technologies to meet the challenges of building in the 21st century. These new wood products attempt to match the desired properties of conventional pressure treated lumber without any of the associated negative environmental and health impacts. Beyond sustainability, the re-engineering of wood is driven by a desire to thwart encroachment by other, more designed, building materials into the building industry and is generally following the trend of technology making both new and old materials smarter through science and research. In the case of wood there are two exemplary technologies which the Ziger/Snead team has recently reviewed for use in a planned LEED Platinum building for the Parks&People Foundation.

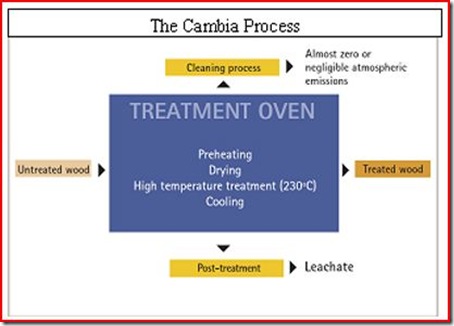

Cambia by Greenleaf

Cambia wood is thermally modified (high heat) to ?improve the dimensional stability and decay resistance of wood in an environmentally responsible and sustainable manner.? The wood, after treatment, is apparently much more resistant to checking, splitting than untreated wood and is very similar to conventional pressure treated lumber in terms of preventing rotting and insect decomposition. All of this is accomplished using almost no chemicals and the thermal treatment is powered by gasses released from the wood itself during low heat combustion. The science is very interesting and is described more thoroughly by the Cambia team:

Wood, by nature is hygroscopic. Free hydroxyl groups absorb and release water with changes in the climatic conditions. Water molecules diffuse into the cell wall and bond to the OH groups, taking up space in the cell wall and causing the cell walls to expand. Wood movement (expansion, contraction, cupping, twisting, warping) is due to the unequal absorption and exorption of moisture. Heating wood at high temperatures in an oxygen free environment causes lignin to flow and hemicellulose to decompose, producing water-insoluble polymers thereby increasing dimensional stability.

As an organic compound, wood biodegrades. Biodegradation requires the presence of oxygen and water in the cell wall. In turn, enzymes metabolize available oxygen and water, causing the cell walls to decompose.

At high heat, free and bound water is eliminated, reducing the point at which the wood is no longer losing or gaining moisture. Wood exhibiting low Equilibrium Moisture Content (EMC) expands and contracts less with changes in relative humidity. Water absorbing hydroxyl groups in the hemicellulose break down.. Water molecules have nothing to bond to.

The energy to thermally modify the wood comes from the wood. Organic compounds are drawn off and reused as a fuel source. Upwards of 80% of the energy required to thermally transform the wood is derived from the wood itself. The heavier tar-like constituents form an amorphous crystalline matrix around the wood fibers, reducing EMC by upwards of 75%. The stabilized wood is less prone to movement (cupping, warping, twisting) contributing to a significantly longer service life.

At high heat, carbohydrates and water are reduced to the point where they are no longer a food source for wood destroying microbes.

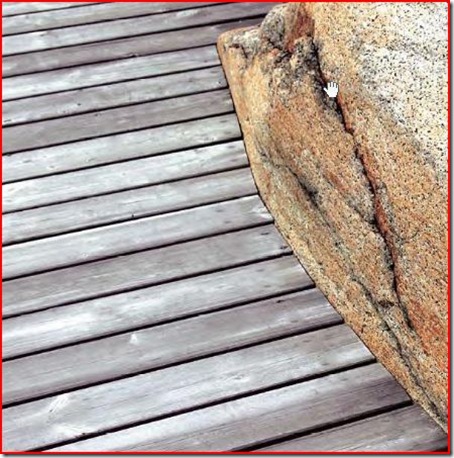

The sample I have is a Poplar (their most used wood species) which actually smells wonderfully charred and is similar in color and texture to Ipe (dark brown). The weathered sample has grayed beautifully over time and has almost no signs of aging. The process can be applied to any wood species and does not affect FSC certification for those interested in LEED credits! Interestingly, we have researched the idea of using lumber reclaimed from a western Maryland barn and having the Cambia treatment applied. ?FSC reclaimed? might even apply so the new building would have FSC certification by using recycled wood from a structure in the region. Beautiful!

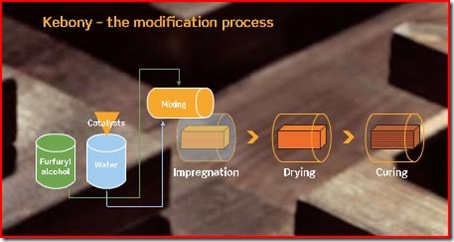

Kebony

Kebony wood is a pressurized treatment process where an bio-based solution is applied to wood in lieu of the conventional chemicals. The result is a harder, more stable wood product with increased resistance to rot and insect attack. The Kebony team describes the treatment process below:

Kebonization is a time-consuming process in which the properties of the wood are enhanced. The wood becomes harder and more stable, and its durability is improved. The liquid used in the process contains a bio-based substance which forms a stable solid inside the wood. The process involves the following four stages:

1. Ingredients are mixed according to a patented recipe.

2. The liquid is applied under pressure.

3. Drying of the wood materials.

4. The wood materials undergo a curing process at temperatures above 100?C.The process is close-looped and the liquid ingredient is recycled during the production process. The furfuryl alcohol used as the input chemical is produced from agricultural waste from sugar cane production.

Kebony is far more stable than other wood types. The only difference that will be noticeable over time is the patination that occurs in wood exposed to the elements.

Cambia and Kebony are both clear examples of how technology can be used improve age old building materials. Instead of creating a new synthetic version of wood, product developers are simply tweaking the existing materials, saving and slightly altering all the established processes for extraction, sales and production. Also worth noting is that in a time of rapid deforestation due to farming and lumber demand, we as designers need products which allow us to use traditional materials sustainably. I look forward to seeing more of these products developed in the future.

Recent Posts

Reimagining Harborplace to Create Space for Both Private Development and Expanded Public Space » Lawyer's Mall Reconstruction Progress » Confronting the Conventions of Customary Practice » Reconceived Facades: New Roles for Old Buildings » Ivy Bookshop Opens for Business! »

Categories

Yellow Balloon Baltimore » Products + Technology » Industry + Practice » Other » Architecture »

Links

Organizations

- USGBC Baltimore Regional Chapter »

- AIA - American Institute of Architects »

- USGBC »

- The Walters Art Museum »

- Green-e »

- Center for Building Performance and Diagnostics (CMU) »

- Green Globes »

- Prefab Lab (UT) »

- Center for Sustainable Development (UT) »

- Architecture 2030 »

- Bioneers »

- Street Films »

- FreeCycle »

- Chesapeake Bay Foundation »

- Archinect »

- BD Online - The Architects Website »

- National Wildlife Foundation »

- Natural Resources Defense Council »

- Overbrook Foundation »

- Merck Family Foundation »

- Ecology Center »

- New Building Institute »

- Neighborhood Design Center »

- The Leonardo Academy »

- ZigerSnead Architects LLP »

- The Rocky Mountain Institute »

- Urban Habitats »

- ACORE - American Council on Renewable Energy »

- Parks and People Foundation of Baltimore »

- Open Society Institute of Baltimore »

- Natural Capital Institute »

- Passive House US »

- Svanen Miljomark »

- Green Restaurant Association »

- Rocky Mountain Institute »

- Green Exhibits »

- Green Roundtable »

- John Elkington - SustainAbility »

- SustainAbility »

- Building America »

- Endangered Species Program - Fish and Wildlife Service »

- Congress for the New Urbanism »

- Urban Land Institute »

- Cool Roof Rating Council »

- Montgomery County (MD) Public Schools Green Building Program »

- National Institute of Standards and Technology Software »

- Scientific Certification Systems »

- Community Greens »

- CBECS »

- CASE - Center for Architecture Science and Ecology »

Interesting Sites

- The Ecologist »

- Treehugger »

- Grist »

- WIRED »

- Planet Architecture »

- MiljoBloggAktuellt - Environmental News Blog (Swedish »

- Sustainable Design Update »

- Eikongraphia »

- World Architecture News »

- The Cool Hunter »

- Design Center »

- ZEDfactory »

- Architen Landrell Associates Ltd. »

- Environmental Graffiti »

- businessGreen »

- Best Green Blogs Directory »

- Groovy Green »

- EcoGeek »

- Urban Ecology »

- Locus Architecture »

- Urbanite »

- A Daily Dose of Architecture »

- Adaptive Reuse »

- Audacious Ideas »

- Big Green Me »

- NOTCOT »

- Sustainable Baltimore »

- Thoughts on Global Warming »

- Green Maven »

- WorldChanging »

- Go For Change »

- Building Green »

- Home Energy Magazine »

- Home Energy Blog »

- FEMA Map Service- Federal Emergency Management Association »

- Architectural Graphic Standards »

- E-Wire »

- Post Carbon Cities »

- Alt Dot Energy »

- Whole Building Design Guide »

- B'more Green »

- EJP: Environmental Justice Partnership »

- Baltidome »

- OneOffMag »

November 23rd, 2009 at 5:11 PM

wood building materi

This is a very good article. I really enjoy hearing good ideas about wood