1006 Morton Street

Baltimore, MD 21201

410.576.9131 | RW1haWw=

February 7 2012

What is Corrugated Corten and Why make Corten AZP?

Corten Steel. It is the stuff of dreams. Red. Rusty. Weathered. Strong. You have seen Corten as the wonderful tilted spheres of Richard Serra and as the nomads of Rick Joy. It looks like the rusted, agricultural, shed roofs of the south eastern and western United States on steroids but in fact is completely engineered to appear that way. You see Corten, or Cor-Ten as it trademarked, is designed and manufactured by US Steel (USS) and "is a group of steel alloys which were developed to obviate the need for painting, and form a stable rust-like appearance if exposed to the weather for several years." Corten is just a material and can come in any thickness from mm to inches to feet thick. It can be a structure or a cladding. Best of all the rust-like abrasive blasting the finish.

You see the product, as it is exposed to the elements, quite literally oxidizes a protective finish around its structural core. This is brilliant in arid climates. The finish 'grows' and then stays relatively stable for years and years. This feature isn't however very good for moist, salty climates like those found here in Baltimore, MD. In fact, US Steel strongly cautions against using Corten in these areas as salt may prevent the protective patina from stabilizing. Pockets of water or constant moisture can also cause the same problem of continued, ongoing, deterioration.

"USS reiterates and reminds that COR-TEN steel sheet products should not be sold when the intended use is for an architectural application, such as roofing and siding. USS has consistently maintained this position because of the risk of corrosion from factors beyond the control of the COR-TEN steel licensee (e.g. improper design, fabrication, erection and/or maintenance)."

This means that Corten can be used for sculpture, structures and decorative elements but not for "roofing and siding" where the material is integral to the weather barrier (moisture control) system of the building, at least in places besides the arid desert south west. Corten comes in several different ASTM grades including A242 (Corten A), A588 (Corten B), and A606 for light gage applications such as corrugated roofing and siding. It is the last grade, A606, which architects typically use in projects and which Ziger/Snead is considering for use in the Center for Parks & People at Auchentoroly Terrace.

The problem we encountered is that we simply have the wrong climate for using A606 corrugated Corten steel as a siding material. We love the look but the weather here in Baltimore swings between Hot/Humid and Temperate and we get a good amount of precipitation. It goes without saying that the client and project team are not willing to gamble on a product when the manufacturer explicitly warns against the conditions on site. So do we have any other options?

Yes! Enter Corten AZP, US Steel's answer to architects and designers who want the patina and enduring strength of Corten without the corrosion issues. This product, released in 2005, is made by coil-coating a Galvalume substrate with a paint finish that mimics the color and texture of naturally aged weathering steel. Included is a base color coat with a contrasting pattern overlay print under a topcoat infused with infrared reflective pigments to provide 'cool roof' characteristics. Currently, US Steel has produced three different finishes: Original Corten AZP, Corten AZP Robust, and Corton AZP Raw. The three vary towards their representation of actual Corten, and range in shade and texture.

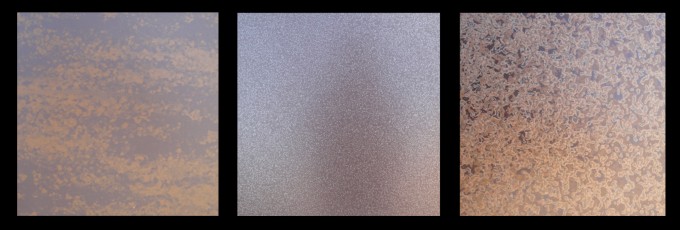

These are just a few of the samples we have received from various manufacturers of Corten AZP. As you can see, there are many different finishes that vary in their representation of Corten.

To the left is actual Corten steel placed next to a steel painted in Corten AZP Raw at the right. Corten AZP Raw is the finish we found to most accurately replicate the rust out of the other samples we have received.

US Steel notes that Corten AZP has:

- Warranted corrosion protection

- Prepainted Galvalume 25-year anti-perforation

- PVDF Paint chalk, peel and fade

- Improved Solar reflectivity / Qualifies as a Cool Roof

- Solar Reflectivity* .282 .087

- Thermal Emissivity* .855 .890

- No unsightly storm-water runoff staining

- High recycled content and total recyclability

Thanks to US Steel we now have two options for getting rugged, rusted, patina rich material on our projects, and climate is not an insurmountable obstacle. For those of you lucky enough to design buildings in areas with little or no precipitation and dry air, use Corten. For the rest of us there is Corten AZP which looks and behaves almost like the real thing without the worry of corrosion. Add cool roof charactaristics and I think you have winning product.

Corten and Corten AZP are both remarkable products that improve the palette available to architects and designers. US Steel should be commended for bringing these unique materials to market.

For more information please visit the US Steel website or "Weathering Steel" on Wikipedia.

Visit the Center for Parks & People at Auchentoroly Terrace project page for information on our final selection (to be updated).

Recent Posts

Reimagining Harborplace to Create Space for Both Private Development and Expanded Public Space » Lawyer's Mall Reconstruction Progress » Confronting the Conventions of Customary Practice » Reconceived Facades: New Roles for Old Buildings » Ivy Bookshop Opens for Business! »

Categories

Yellow Balloon Baltimore » Products + Technology » Industry + Practice » Other » Architecture »

Links

Organizations

- USGBC Baltimore Regional Chapter »

- AIA - American Institute of Architects »

- USGBC »

- The Walters Art Museum »

- Green-e »

- Center for Building Performance and Diagnostics (CMU) »

- Green Globes »

- Prefab Lab (UT) »

- Center for Sustainable Development (UT) »

- Architecture 2030 »

- Bioneers »

- Street Films »

- FreeCycle »

- Chesapeake Bay Foundation »

- Archinect »

- BD Online - The Architects Website »

- National Wildlife Foundation »

- Natural Resources Defense Council »

- Overbrook Foundation »

- Merck Family Foundation »

- Ecology Center »

- New Building Institute »

- Neighborhood Design Center »

- The Leonardo Academy »

- ZigerSnead Architects LLP »

- The Rocky Mountain Institute »

- Urban Habitats »

- ACORE - American Council on Renewable Energy »

- Parks and People Foundation of Baltimore »

- Open Society Institute of Baltimore »

- Natural Capital Institute »

- Passive House US »

- Svanen Miljomark »

- Green Restaurant Association »

- Rocky Mountain Institute »

- Green Exhibits »

- Green Roundtable »

- John Elkington - SustainAbility »

- SustainAbility »

- Building America »

- Endangered Species Program - Fish and Wildlife Service »

- Congress for the New Urbanism »

- Urban Land Institute »

- Cool Roof Rating Council »

- Montgomery County (MD) Public Schools Green Building Program »

- National Institute of Standards and Technology Software »

- Scientific Certification Systems »

- Community Greens »

- CBECS »

- CASE - Center for Architecture Science and Ecology »

Interesting Sites

- The Ecologist »

- Treehugger »

- Grist »

- WIRED »

- Planet Architecture »

- MiljoBloggAktuellt - Environmental News Blog (Swedish »

- Sustainable Design Update »

- Eikongraphia »

- World Architecture News »

- The Cool Hunter »

- Design Center »

- ZEDfactory »

- Architen Landrell Associates Ltd. »

- Environmental Graffiti »

- businessGreen »

- Best Green Blogs Directory »

- Groovy Green »

- EcoGeek »

- Urban Ecology »

- Locus Architecture »

- Urbanite »

- A Daily Dose of Architecture »

- Adaptive Reuse »

- Audacious Ideas »

- Big Green Me »

- NOTCOT »

- Sustainable Baltimore »

- Thoughts on Global Warming »

- Green Maven »

- WorldChanging »

- Go For Change »

- Building Green »

- Home Energy Magazine »

- Home Energy Blog »

- FEMA Map Service- Federal Emergency Management Association »

- Architectural Graphic Standards »

- E-Wire »

- Post Carbon Cities »

- Alt Dot Energy »

- Whole Building Design Guide »

- B'more Green »

- EJP: Environmental Justice Partnership »

- Baltidome »

- OneOffMag »